-

Car Reviews

- Car News

-

Car Comparisons

Latest comparisons

- Chasing Deals

The process of making batteries for electric cars is a complex one, but here we break down what goes into producing the power of the future

Electric cars wouldn’t exist without batteries. The core power source that runs onboard computers, electric motor powertrains and air conditioning systems, to list just a few, comes down to the onboard battery pack.

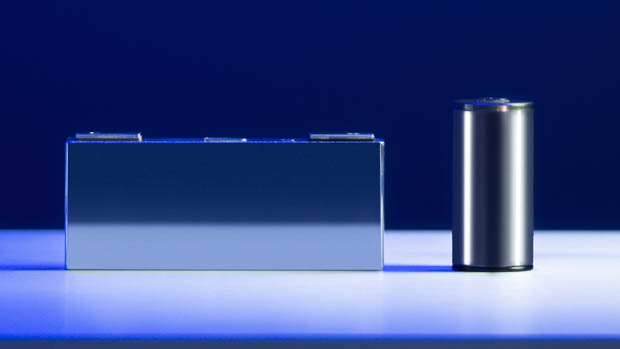

Today, most batteries are made of a lithium-ion construction, however other common battery types include nickel-metal hydride and lithium-iron phosphate.

But we want to know how these batteries come into existence, what they are made of and how they are produced for the mass car market.

In this Chasing Cars guide, we’ll mainly focus on the lithium-ion battery, what it’s made of and how it’s built.

The founding principles of electric car batteries revolve around minerals found beneath our feet.

One of the core ingredients of a lithium-ion electric car battery is, yep, lithium. Lithium salts are commonly found in large underground brine wells and also as ore (natural rock or similar sediment).

The most common way that humans are able to extract lithium from the earth is through drilling into brine deposits and then evaporating the brine liquid to ultimately form a solid. In a simplified way, this is then mixed with sodium carbonate to make lithium carbonate.

Why use lithium, after all?

It’s a metal that offers excellent heat and electrical conductivity, perfect for use in batteries.

However, lithium is also used for a variety of different applications, including as a medication.

It’s been used in the tech industry commercially since 1991 when Sony released its first mass-market battery, however the first prototype of this kind of technology was invented by Japanese chemist Akira Yoshino back in 1983.

What minerals and elements are needed to make an electric car battery?

Despite the name lithium-ion, lithium is not the key material used for electric car batteries. A combination of raw materials including aluminium, copper and iron are frequently used, along with more expensive precious metals such as cobalt, nickel and manganese.

A study by Elements reported that in 2020, the largest mineral content in an electric car battery was in fact graphite, followed by aluminium, nickel, copper and steel.

Lithium made up a relatively small amount of a battery – just 3.2 percent of an entire battery’s chemical structure.

The study also said that the 60kWh battery pack it inspected used roughly 185 kilograms of minerals.

How are these minerals dispersed within a battery?

If we break down each of the important parts of a battery pack, the cathode is made up of aluminium, nickel, lithium, iron, cobalt and manganese. The cathode is very often the most expensive part of an electric car’s battery.

The anode, meanwhile, is almost entirely graphite.

The cell casing is made up of both aluminium and steel, while the current collectors are made up of both aluminium and copper.

The battery pack found in an electric car has many different parts to make it work. An average electric car battery can include the following parts:

The building of an electric car battery is a complex task, so we’ve broken it down into segments, as it has been done by the RWTH AACHEN University in Germany, as you can read here.

Here are the various steps for building battery cells for wider production.

There are plenty of steps, clearly showcasing the complexities and level of detail needed to build such complex battery systems.

Battery packs are produced by large battery manufacturers such as CATL, Panasonic, LG, Samsung and BYD, rather than the car makers themselves.

Global car manufacturers often do not build the batteries that go into their own cars. Chinese automakers BYD and GWM are some of the only battery and automobile producers that currently use their own batteries.

The common lithium-ion battery works based on an anode (negative) and a cathode (positive).

Electrolytes (lithium-ions) move across from the cathode to the anode during charging and in the opposite way when discharging, like for example, when powering the onboard electric motor.

Modern batteries are more complex than this, however, and contain software and sensors to ensure they don’t overheat.

Voltage regulators and temperature sensors are commonplace to prevent high temperatures or fires from occuring.

Most electric vehicles on sale today have active cooling systems to regulate the heat from their battery packs.

Cooling systems pump coolant past the battery pack cells to keep them at a safe operating temperature.

The Tesla Model 3, for example, has an extensive battery cooling system that runs through and around the battery pack to keep the battery at the optimal temperature for both efficiency and performance.

There are several other battery constructions out there, some of which are now defunct. These include:

Latest guides

About Chasing cars

Chasing Cars reviews are 100% independent.

Because we are powered by Budget Direct Insurance, we don’t receive advertising or sales revenue from car manufacturers.

We’re truly independent – giving you Australia’s best car reviews.